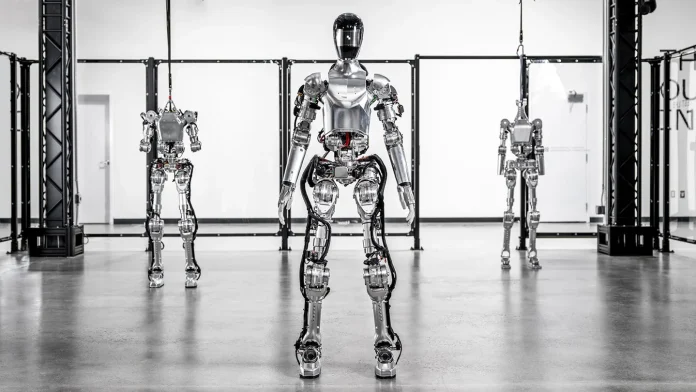

In recent moves, both Tesla and BMW are exploring the integration of AI-powered humanoid robots in their car manufacturing processes. BMW has partnered with Figure, a California startup, to deploy artificially intelligent robots in its automotive manufacturing plant in Spartanburg, South Carolina. Unlike traditional single-purpose robots, Figure’s robots are designed to perform a variety of tasks, addressing tedious or unsafe activities for human workers.

Figure’s humanoid robot, called Figure 01, stands at 5 feet 6 inches tall, can carry 44 pounds, operates for five hours on a full charge, and walks at a speed of 2.7 miles per hour. The collaboration aims to identify specific areas within BMW’s manufacturing processes where these robots can enhance productivity, reduce costs, and improve overall safety.

Tesla is also developing a similar robot named Optimus, intended for manual labor on its factory floors. Elon Musk envisions the potential for Optimus to serve as a personal butler and has expressed the belief that Tesla’s robotics division could eventually surpass its car business.

The adoption of humanoid robots in car manufacturing could impact human jobs, as automation and the shift to electric cars are already influencing the automotive workforce. Figure sees its robots as a solution for filling the approximately 10 million unfilled jobs in the U.S. that people may not want.

While the prospect of humanoid robots taking over complex manufacturing processes is not immediate, Figure’s robot has demonstrated learning capabilities by successfully making coffee using a Keurig machine after observing people for 10 hours. Despite starting with a simple task, this showcases the potential for robots to acquire new skills through observation and adaptation.